Reinforcing bars, commonly known as rebars, are critical components in modern construction, providing strength and durability to structures. Their incorporation into concrete helps mitigate the risk of cracking and ensures stability over time. In this guide, we will explore the importance of rebars, how to select the right type, the installation process, safety measures, and maintenance practices to ensure the longevity and integrity of your structures.

Understanding the Importance of Rebars in Construction

Rebars play a vital role in enhancing the mechanical properties of concrete. Concrete is strong in compression but weak in tension; thus, reobars are embedded in concrete to increase its tensile strength. This synergy results in a composite material that can support heavy loads and withstand environmental stresses.

The Role of Rebars in Maintaining Structural Integrity

The inclusion of rebars is essential for preventing structural failures. They help distribute loads evenly throughout the concrete, limiting the potential for cracking and deformation. In addition, rebars provide the necessary ductility, allowing structures to flex under stress without immediately collapsing.

Furthermore, rebars contribute to the resilience of structures against natural disasters, such as earthquakes. Properly designed and installed rebar systems can absorb and dissipate energy, enhancing the safety of buildings in seismic zones. This becomes particularly crucial in regions prone to seismic activity, where the ability of a structure to endure oscillations and ground movement can mean the difference between survival and catastrophe.

Different Types of Rebars and Their Uses

There are various types of rebars available, each suited to different applications and environmental conditions. The most common types include:

- Plain Rebars: Often used in low-stress applications, such as landscaping and minor concrete projects.

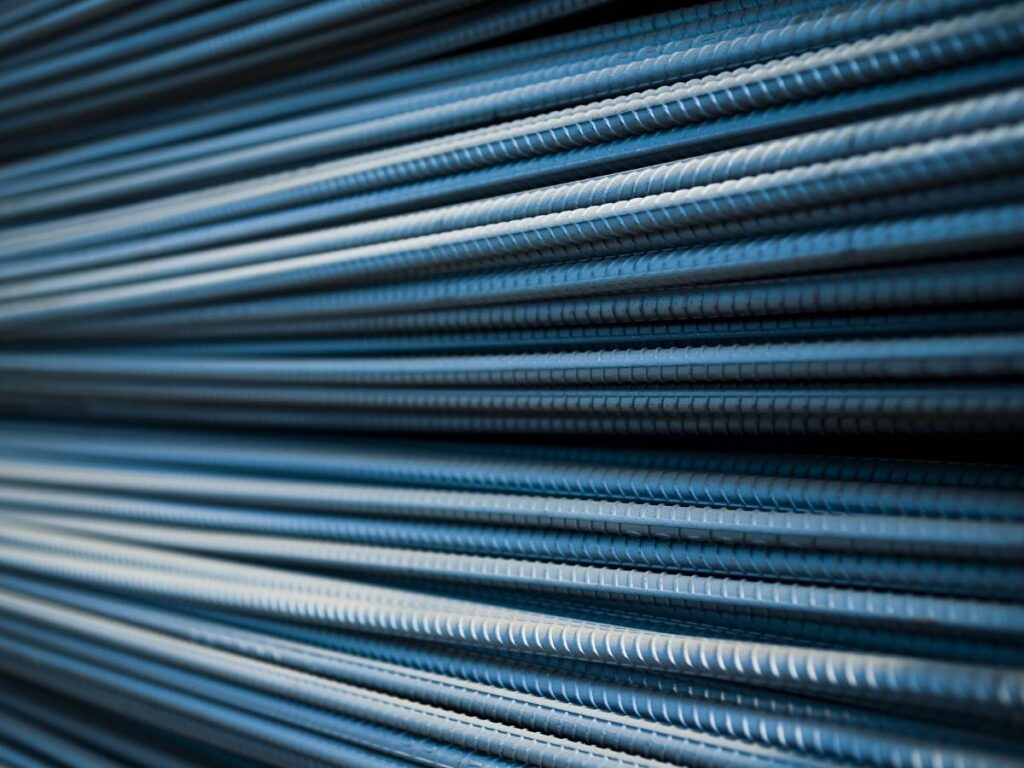

- Deformed Rebars: Featuring ridges or bumps, these rebars are used in major construction projects for improved bonding with concrete.

- Epoxy-coated Rebars: Ideal for high-corrosion areas, these rebars are coated to protect against rust and deterioration.

- Stainless Steel Rebars: Known for their excellent corrosion resistance, these are ideal for projects exposed to harsh environments.

In addition to these common types, there are also specialised rebars designed for specific applications. For instance, fibre-reinforced polymer (FRP) rebars are increasingly gaining popularity due to their lightweight properties and resistance to corrosion, making them suitable for marine structures and bridges. Moreover, advancements in technology have led to the development of high-strength rebars, which allow for thinner concrete sections while maintaining structural integrity. This innovation not only optimises material usage but also contributes to more sustainable construction practices, reducing the overall carbon footprint of building projects. Read more about integrity on https://academicintegrity.ucsd.edu/

Selecting the Right Rebar for Your Project

Making the correct choice in rebar selection is vital for the success of any construction project. It not only affects the structural integrity but also impacts the overall cost and longevity of the building.

Factors to Consider When Choosing Rebars

Several factors should guide your selection process, including:

- Load Requirements: Understand the load-bearing specifications and use rebars that comply with those standards.

- Environmental Conditions: Assess the location of your project, taking into account potential corrosion risks due to moisture, chemicals, or extreme temperatures.

- Project Budget: Balance the cost of different types of rebars with the expected longevity and performance of the structure.

- Regulatory Standards: Ensure that your selection meets local building codes and industry standards.

Common Mistakes to Avoid in Rebar Selection

To ensure you are selecting the right rebar, be wary of common pitfalls, such as:

- Choosing the lowest-priced option without considering quality.

- Ignoring the environmental factors that could affect the rebar.

- Failing to consult with a structural engineer when making selections for large projects.

- Neglecting to consider the rebars’ compatibility with the concrete mix being used.

In addition to these considerations, it is also essential to think about the type of rebar that best suits your specific project needs. For instance, epoxy-coated rebar is an excellent choice for projects in coastal areas or regions with high humidity, as it provides an extra layer of protection against rust and corrosion. Similarly, stainless steel rebar, while more expensive, offers superior durability and resistance to environmental factors, making it an ideal option for structures that require a longer lifespan. Click here to find more about humidity.

Furthermore, the diameter and grade of the rebar should also be taken into account. Higher grade rebars, which are stronger and more ductile, can be crucial for high-stress applications, whereas standard grades may suffice for lighter constructions. It is also worth noting that the spacing and placement of rebars within the concrete can significantly influence the overall performance of the structure, necessitating careful planning and adherence to best practices in rebar installation.

A Step-by-Step Guide to Installing Rebars

Installing rebars correctly is crucial for the structural performance of the concrete. The following steps provide a comprehensive guide to ensure proper installation.

Preparing for Rebar Installation

Before starting the installation, thorough preparation is essential. Begin by reviewing the structural plans and ensuring all materials are on site. Key steps include:

- Site Assessment: Assess the site for any potential obstacles or hazards that may interfere with the installation process.

- Cutting and Bending: Properly cut and bend the rebars according to the project specifications. Use the appropriate tools to ensure precision.

- Placement Support: Employ supports, such as chairs or spacers, to establish the correct position and spacing of the rebars within the pour.

The Process of Rebar Installation

Once prepared, the installation process can begin. Follow these steps:

- Setting up the Framework: Construct the formwork where the concrete will be poured, ensuring it is sturdy and correctly aligned.

- Positioning the Rebars: Lay the rebars in the designated areas, following construction drawings to maintain the correct spacing and layering.

- Securing the Rebars: Use wire ties to fasten the rebars at intersections, ensuring they do not move during the concrete pour.

- Final Checks: Review the placement of all rebars to ensure compliance with structural plans before pouring concrete.

It is also important to consider the environmental conditions that may affect the installation process. For instance, if the weather is particularly wet or windy, it may be necessary to take additional precautions to protect the rebars from corrosion or displacement. Furthermore, ensuring that the site is clean and free from debris will not only facilitate a smoother installation process but also enhance safety for all personnel involved. Adequate lighting should be provided to ensure visibility, especially in low-light conditions, as this can prevent errors during the critical stages of rebar placement.

Additionally, understanding the different types of rebars available can greatly influence the installation process. For example, epoxy-coated rebars are often used in environments prone to corrosion, while stainless steel rebars offer superior durability and resistance. Familiarising oneself with these materials and their specific applications can help in selecting the right type for the project at hand, ultimately contributing to the longevity and safety of the structure being built. Proper training and adherence to safety protocols during installation cannot be overstated, as they are vital for minimising risks and ensuring a successful outcome.

Ensuring Safety During Rebar Installation

Safety is paramount during any construction activity, including rebar installation. The risks involved can be mitigated through proper equipment and practices.

Essential Safety Gear for Rebar Installation

Construction workers should always wear appropriate safety gear, including:

- Safety helmets to protect against falling objects.

- Protective gloves to prevent cuts and scrapes from sharp rebar edges.

- Steel-toed boots to shield feet from heavy loads.

- Safety glasses to safeguard against flying debris.

Safety Precautions to Follow During Installation

In addition to personal protective equipment, following specific safety precautions is essential:

- Maintain a Clean Work Area: Keep the site tidy to avoid tripping hazards.

- Be Mindful of Surroundings: Stay alert to activities around you, especially when heavy machinery is in operation.

- Use Proper Lifting Techniques: When moving rebar, lift with your legs to avoid back injuries.

- Communicate Clearly: Establish a system of communication to ensure all team members are aware of safety protocols.

Moreover, it is crucial to conduct regular safety briefings before commencing work each day. These briefings should cover the specific tasks for the day, potential hazards associated with those tasks, and the importance of adhering to safety protocols. Engaging workers in discussions about safety not only reinforces the importance of these measures but also empowers them to voice concerns or suggest improvements based on their experiences. This collaborative approach can significantly enhance the overall safety culture on site.

Additionally, training sessions on the correct handling and installation of rebar should be a standard part of worker education. These sessions can include demonstrations of safe practices, such as how to properly tie rebar and the use of tools designed to minimise injury risk. By investing time in training, employers can ensure that their workforce is not only skilled but also vigilant about safety, ultimately leading to a more efficient and secure working environment.

Maintaining and Inspecting Rebars Post-Installation

Once the concrete has cured and the rebars are permanently set, ongoing maintenance and inspection are necessary to maintain structural integrity and safety.

Routine Maintenance Tips for Rebars

Although rebars are generally low maintenance, certain practices can prolong their lifespan:

- Regularly check for visible signs of corrosion or damage.

- Inspect exposed rebars periodically, especially in harsh environments.

- If signs of rusting appear, take immediate action to treat the affected areas.

How to Inspect Rebars for Potential Issues

Conducting thorough inspections helps identify issues before they escalate. Key procedures include:

- Visual Inspections: Look for signs of cracks, rust, or any bending in exposed rebars.

- Mechanical Testing: For critical structures, consider conducting pull-out tests to ensure rebars are securely bonded within the concrete.

- Documentation: Keep detailed records of inspections and maintenance actions taken, which can be vital for long-term structural health assessments.

By understanding the importance of rebars, selecting the right type, ensuring proper installation, adhering to safety measures, and performing regular maintenance, you can significantly enhance the structural integrity of your construction project. Following these guidelines not only improves the safety and durability of your structures but also helps in complying with relevant regulations and standards in the construction industry.